White Papers

White Papers

Safety light curtains or safety laser scanner?

In the safety laser scanners market, Datasensing qualifies as one of the few companies to offer its own developed and manufactured devices.

Datasensing is also one of the world's main safety light curtains manufacturers.

So, who better to answer the question?

Safety Laser Scanner: how it works?

Safety laser scanners are developed for the worker protection in potentially hazardous areas and machinery.

According to EN 61496-1 and EN 61496-3, safety laser scanners are considered Electro-Sensitive Protecting Equipment (ESPE) and Active Optoelectronic Protective Device Responsive to Diffuse Reflection (AOPDDR), defined as "Device with a sensor function produced by optoelectronic send and receive elements which detects the diffuse reflection of optical radiation generated in the device due to the presence of an object in a defined two-dimensional protective field.”

Simply put, a safety laser scanner is a device that emits a laser beam that rotates over an angle of typ. 190° up to 275°, detecting the presence and distance of any objects or operators, based on the time of flight of the reflected light.

Datasensing enhanced safety laser scanners are inside SLS product line.

Where are Safety Laser Scanners used?

Safety laser scanner applications can be STATIC by detecting the operator’s access or presence in an area, for example a robotic cell, or DYNAMIC by mounting the laser scanner on automated guided vehicle (AGV) and detecting obstacles or operators on its way.

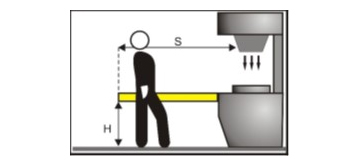

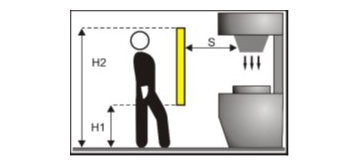

Safety laser scanners can also be used in applications with horizontal mounting (optical axis ≤30°), or vertical mounting (optical axis >30°).

With horizontal mounting, the detection usually occurs on a plane close to and parallel to the floor, with typical applications in hazardous areas that can be approached by a person, such as open robotic cells or machinery for processing metal, wood, or other materials.

In vertical mounting, the detection occurs in a plane perpendicular to the floor, effectively creating a barrier in which access protection can be configured, such as in conveyor or palletizing areas.

Safety Light Curtain: how it works?

Safety light curtains are also used for the protection of worker in potentially hazardous areas and machinery.

According to EN 61496-1 and EN 61496-2, safety light curtains are considered Electro-Sensitive Protecting Equipment (ESPE) and Active Opto-electronic Protective Device (AOPD) defined as "Device with a sensor function produced by optoelectronic send and receive elements which detect a break in the optical radiation generated in the device due to the presence of an opaque object in the defined protective field.”

Basically, it can be detected when an object, operator, or parts thereof (e.g., finger, hand, or arm) interrupts one or more light beams.

Datasensing latest safety light curtains are inside SH4 product line.

Where are Safety Light Curtains used?

Safety light curtain applications can only be STATIC for hazardous point protection. For example, close to metalworking machines, or access protection to dangerous areas, such as conveyors, palletizers, and automated warehouses.

Again, safety light curtains can be installed with horizontal or vertical mounting.

With horizontal mounting, the detection usually occurs on a plane parallel to the floor. Typical applications include detection of an operator presence in a protected area before starting a hazardous process or machinery.

In vertical mounting, the detection occurs in a plane perpendicular to the floor, effectively creating a barrier and an access control to dangerous areas or machinery parts.

Safety Laser Scanner or Safety Light Curtain, how to choose?

The selection of a safety sensor for use in machinery is part of the overall risk reduction process.

Such process starts with the analysis and evaluation of all possible risks the machine presents and ends with the validation and testing of the safety system.

The safety sensor chosen should fulfill any safety requirements specific to the machine. If there are no machine-specific requirements, the safety system should be designed to comply with all general safety and health standards, such as: EN ISO 12100: 2010 Safety of machinery – General principles for design – Risk assessment and risk reduction; EN ISO 13849-1: 2008 Safety of machinery - Safety-related parts of control systems. Part 1: General principles for design; EN ISO 13849-2: 2012 Safety of machinery - Safety-related parts of control systems. Part 2: Validation.

The overall system design dictates the parameters the safety sensors must meet.

The following list of parameters and functions related to safety sensors can serve as a checklist to help in the selection process.

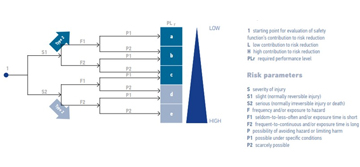

1. Performance level (PL) and required performance level (PLr)

Performance level is one of five discrete levels (a, b, c, d, e) that specify the ability of the safety-related part of a control system to perform a specific safety function.

The performance level depends on system design, reliability of components used, diagnostic coverage of dangerous faults and ability of the safety parts to avoid common cause and systematic faults.

The minimum required Performance Level (PLr) to reduce a risk is based on three factors:

i. the severity of injury;

ii. the frequency of exposure to hazard;

iii. the possibility to avoid the hazard.

Safety laser scanners have typically a PL d, whereas safety light curtains can reach PL c in Type 2 and PL e in Type 4.

Datasensing basic safety light curtains are inside SG2 product line for type 4 and SG4 for type 4.

2. Safety integrity level (SIL)

Safety integrity level expresses the degree of reliability reached by a safety device.

The higher the SIL integrity level of a safety system or function, the lower the probability that the safety system or function will fail.

In practice, also considering the Probability of a dangerous Failure per Hour (PFHd), a low performance level PL c corresponds to a SIL 1, a PL d to a SIL 2, and a PL e reaches a higher level SIL 3.

3. Type

Safety laser scanners are Type 3, whereas safety light curtains are classified as Type 2 or Type 4, depending on their design and optical performance.

The maximum PL that can be reached with a Type 2 is PL c, while for a Type 4 the maximum is PL e.

Therefore, to reduce the highest risks on machines, Type 4 should be used.

4. Detection Capability or Resolution

The detection capability is the diameter of the smaller object that will activate the device when it’s placed in any point of the detection zone.

The value of the detection capability, together with response time, is crucial to calculating the minimum safety distance required between the light curtain and the dangerous zone.

Safety Laser Scanners other selection criteria

More technical specifications to consider are:

- Working distance, with different safety and warning values;

- Number of programmable zones and areas;

- Aperture angle over which the detection is made;

- Minimum value of response time;

- Other functions like speed measurement, shut-off, master/slave, programming and monitoring over Ethernet, FieldBus interfaces, etc.

Safety Light Curtains other selection criteria

Other specifications to consider are:

- Resolution (eg. finger 14 mm, hand 30 mm, or body with 2, 3, or 4 beams);

- Controlled height, which can range from 150 mm up to 3 m or more;

- Operating distance between the emitting and receiving units;

- Housing sizes, material, and mechanical features such as IP protection or no dead zone;

Safety advanced functionalities

Other selection criteria can be the presence of advanced functionalities, e.g., Auto/Manual restart, EDM, Muting, Override, Blanking, Cascading, Anti-interference, etc.

Restart interlock

This function prevents automatic restarting of a machine in three cases:

- after actuation of the sensing device during a hazardous part of the machine operating cycle

- after a change in mode of operation of the machine

- after a change in the means of start control of the machine

The start interlock instead prevents an automatic machine start when the electrical supply is switched on, or it is interrupted and restored. Both these functions are achieved by setting the Manual Restart.

External device monitoring (EDM)

This function monitors the state of control devices which are external to the safety device.

The safety device shall go to a lock-out condition when an incorrect state is detected in one of the devices being monitored by the EDM.

Muting and Override

The safety device can be forced in a temporary automatic suspension of a safety function(s), for example to allow the passage of materials, while detecting instead an operator thanks to specific muting sensors.

Muting function has safety requirements:

- it’s independent from the operator intervention

- the muting start after a sequence of at least two signals

- according to the risk assessment, a muting indicator can be needed

- it’s temporary: when a time limit is reached, it must stop

- the muting sensors must be placed so that they detect actual presence of the load

- specific machine regulations (type C standard) must always be followed

Blanking

This function allows masking of one or more areas, each of a defined size, either locally fixed (Fixed Blanking) or movable (Floating Blanking) in the detection zone.

In this way objects or machine parts can be masked and not considered in the protected area.

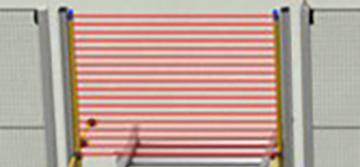

Cascading

This feature allows to connect two or more light curtains to each other, building a system that works as a single device, also allowing the protected height to be increased or different geometries to be constructed, either square or at other angles.

Anti-interference

This is necessary when two or more devices are mounted close together, or even side by side, to prevent security detection from being disturbed.

What products does Datasensing recommend?

Datasensing offers SLS Safety Laser Scanners, distinguished by the completeness of range and ease of use, while among Safety Light Curtains the choice ranges from the best-selling SG4 series to the brand new SH4 with improved environmental features and extended functionality, or from the super-compact SLIM series to the world's unique IP69K stainless steel and hygienic design SG4-H for pharmaceutical aseptic environments.