White Papers

White Papers

What are area sensors?

Definition of Area Sensors

Area sensors can be defined as multi-beam photoelectric sensors.

This type of sensor is typically used to monitor large areas by detecting or measuring objects passing through a specific barrier.

Also known as "array sensors”, they can be conceived as a group of photocells stacked on top of each other.

Area sensors grant several advantages compared to a set of piled up photocells:

- Simplified wiring: area sensors require to connect just one or two cables no matter the height of the area to control. On the contrary, a stack of photoelectric sensors can easily result in dozens of cables to connect

- Integrated signal processing:area sensors can process the signals coming from each beam on board eliminating the need for complex and time-consuming programming on the PLC.

- Application flexibility:area sensors typically offer multiple configuration options to tackle the most common application needs. For example, they can be programmed to drive an analogue output proportional to the height of the object that has been detected.

- Ease of installation: all optical beams come factory pre-aligned thus simplifying the mechanical installation in the field.

- Resolution and detection accuracy: thanks to sophisticated optical design, beam pitch can go down to few millimeters offering very accurate detection and measurement capabilities.

What are the typical applications and when are they meant to be used?

Area sensors are used in either object detection and measurement.

Typically, they are installed orthogonally to the travel direction of the object:

In some applications, area sensors are required as the objects to detect are irregular or their position is somehow unpredictable.

Using a traditional single-beam photoelectric sensor might easily result in unstable or unreliable object detection.For example, food and beverage goods wrapped in soft packages like pasta, chips, diary or backed products, etc…

Other hard-to-detect examples are transparent goods or objects with holes like containers, crates, totes or pallets on conveying systems:

Detection of irregular shapes with holes

Detection of glass sheets

Additionally, area sensors are often used to detect very thin objects like flyers or envelopes in automated sorting systems.

Panels’ thickness detection

Area sensors are able not only to detect but also measure the height or width of an object.

Typical examples can be found in end-of-line or logistics applications.

This means that area sensors can be used to measure the height of carton boxes or pallets.

Another application can be found also in automated painting systems with the aim to measure the dimensions of wooden panels.

Typical examples can be found in end-of-line or logistics applications.

This means that area sensors can be used to measure the height of carton boxes or pallets.

Another application can be found also in automated painting systems with the aim to measure the dimensions of wooden panels.

Objects with holes (pallet) detection

Area sensors are also widely adopted in automated vending machines to detect goods falling down into the basket after the user selection and payment.

This control is extremely important to make sure the machine is properly working and products have been dispensed correctly.

This control is extremely important to make sure the machine is properly working and products have been dispensed correctly.

Vending machine: detection of falling goods

How does an Area Sensor work?

Area sensors are usually made by two distinct units:

- the "emitter”: embedding an array of LEDs

- the "receiver”: integrating a group of photodiodes.

The detection is based on the through-beam optical principle.

The LEDs are emitting light beams that are collected by the photodiodes.

When an object come across the area sensor, one or more light beams get interrupted thus triggering the activation of the outputs.

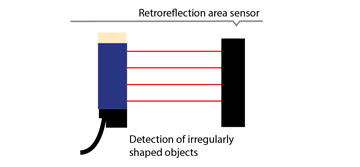

Area sensors can also use the polarized retro-reflection optical principle.

In this case, emitter and receiver are embedded in one single unit, having a reflector on the opposite side.

The beam is emitted by the LED, hits the reflector, bounces back and is collected by the photodiode.

If no light is received back by the photodiode, it means an object has interrupted the light beam

Through beam sensors or retroreflective sensors: what to choose?

Through beam area sensors are relatively simple devices that require two active units: emitter and receiver. These units can be powered up and aligned one in front of the other.

They are usually based on non-visible infrared light and they can manage fairly big working distances (i.e. wide openings) while delivering high detection accuracy and resolution.

Retroreflective area sensors have just one active unit to be wired up thus reducing the installation complexity and costs.

The emitted light is usually visible red to simplify the alignment procedure.

Retroreflective area sensors are suitable for small to mid-size openings.

However, they have lower resolution than through-beam sensors.

This is due to the light's travel.

Parallel or crossed beams?

Most advanced area sensors typically offer two operating modes:

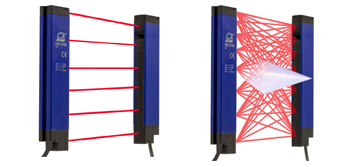

Parallel beams: in this scenario, all light beams are parallel each other.

The area sensor can detect the presence of an object if its height is equal or greater than the beam pitch.

The device is able not only to detect the presence of the object but also to measure it.

Crossed beams: in this operating mode, light beams are crossed, generating a denser detection pattern.

Area sensors can find small objects like sheets or panels, but they can't measure any related dimension.

Parallel beams and Crossed beams ( for thickness objects)

The Datasensing portfolio

Datasensing offers a very comprehensive portfolio of area sensors.

They can be used in various applications and addressing different performance and price point requirements.

AS1

AS1 is a simple solution for detecting very thin objects thanks to its crossed beam optical design.

Coming in a compact mechanical housing, AS1 can control a height of 100mm.

BX10 and BX80

They are crossed beam area sensors, similar to AS1 and BX10/80 models.

BX sensors have been designed to operate in very harsh environments thanks to their sturdy plastic housing reinforced with fiber glass.

Some models have an air cooling inlet for installing the sensor near hot parts in metalworking machines.

Other models are IP69K rated for harsh and washdown environments or ATEX with category 2GD and 3GD.

BX10 beam pitch is 10mm allowing to detect objects down to 5mm, while BX80 features 6mm beam pitch to detect even smaller parts (down to 2mm).

CX

CX Series comes in a very compact and thin aluminum profile.

In addition, CX has no dead zone therefore it can detect the presence of objects along the entire frontal window.

Several models are available controlling up to 960mm height.

The first one, with 32 optics working both in parallel and crossed beam modes, delivering accurate detection even for very thin objects.

CX Series offers a complete set of digital and analogue outputs to be integrated with PLCs seamlessly.

DS2

DS2 is the ideal solution for applications in the end-of-line and intralogistics requiring big area coverage.

With controlled heights up to 1950mm, DS2 integrates parallel beams to detect and measure objects like carton boxes or pallets.

DS2 features extended connectivity, offering not only digital and analogue outputs but also Ethernet communication.

CR Series

CR are retroreflective polarized area sensors.

Differently from the product lines mentioned previously, CR Series is based on only one active unit and a reflector.

This makes the installation of the product in the field quick and easy.

In addition, the visible red light lets the operator align the unit in an extremely intuitive way.

CR series delivers excellent detection performance and no mutual interface also in case of transparent objects, thanks to its polarized emission.

The product also offers state of the art connectivity featuring IO-Link communication.

NX

In addition to the product lines presented above, Datasensing develops solutions specifically meant for automated vending machines.

In this scenario, the NX devices are naked with no external housing to better fit.

Light beams are usually crossed to detect even small objects.

Tropicalized versions are also available for applications in cold vending machines, withstanding lower temperature and presence of moisture.

Thanks to the experience and know-how developed along years of successful applications, Datasensing is able to design fully customized solutions to better accommodate specific requirements in terms of dimensions, beam pitch and connectivity.